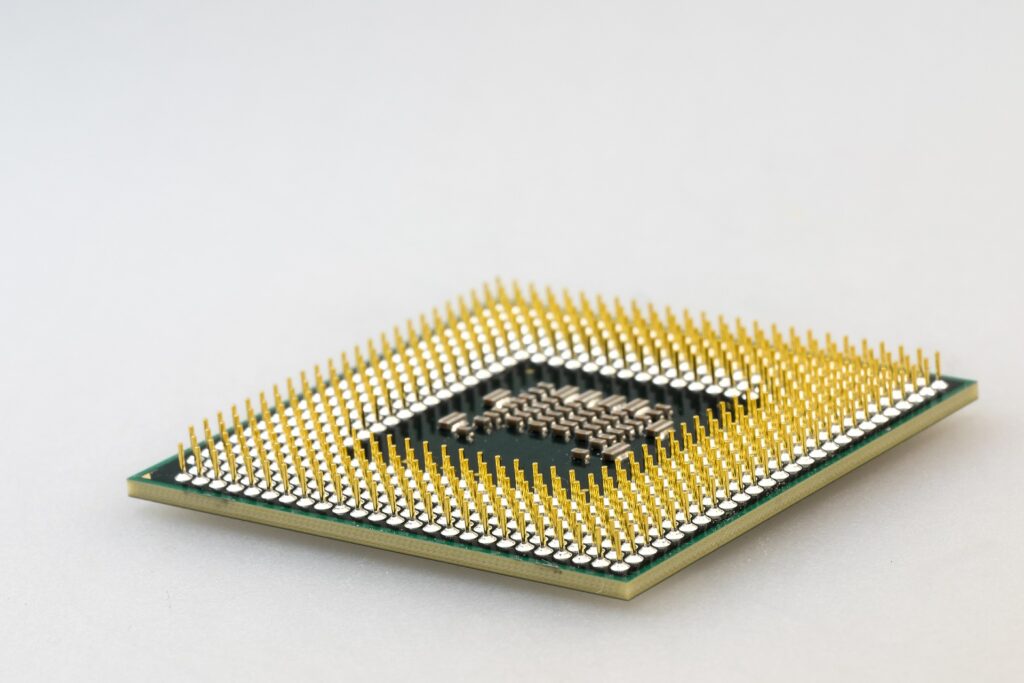

Computer chips (semiconductors) are used in millions of items, including vehicles, washing machines, cell phones, and much more.

With not enough of them to match industry demand right now. As a consequence, a lot of popular goods are out of stock.

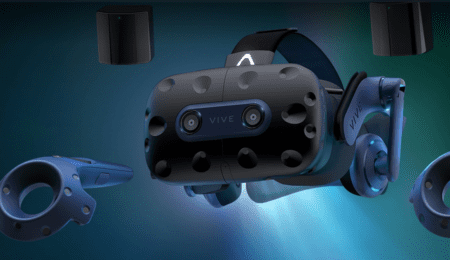

Purchasing a PS5 has become almost impossible. With production at significant plants such as Toyota, Ford, and Volvo have slowed right down or has come to a complete stop. Smartphone makers are also feeling the pressure, with Apple forecasting a drop in iPhone sales due to the shortage.

Even firms that aren’t directly related to computer chips, such as CSSI International, a US-based manufacturer of dog grooming devices, are feeling the consequences.

A few customers have already noticed these problems. Because new cars, which contain thousands of small chips, are in short supply.

Kris Halpin, a North Warwickshire-based musician, is one of many who has been disappointed. Mr Halpin has cerebral palsy and uses the Motability programme to lease an automobile.

According to the scheme’s terms, his current lease expires in October, and he must replace his automobile before then. However, his local dealership has informed him that the car he bought would not be delivered until January of the following year.

Mr Halpin, who uses a wheelchair, adds, “As a handicapped person, I am very, really dependant on my automobile.” “I simply couldn’t travel past my drive without my automobile where I reside.”

Thankfully, Mr Halpin reports that Motability has agreed to extend his existing car’s lease and insurance until the new one arrives.

Even more, items may probably be affected by the shortfall in the following months, especially around Christmas.

What is happening?

In current goods, the chips in limited supply serve a variety of activities, and there are sometimes many of them in a single device.

1bitsquared, an electrical hardware firm based in the United States, was founded and is owned by Piotr Esden-Tempski. On his books are thousands of electrical interface boards that allow students and manufacturers to connect a variety of gadgets to their computers.

On the other hand, Mr Esden’s Tempski suppliers say that some of the components he uses will be unavailable for at least a year.

Less visible manufacturing challenges have also impacted the availability of critical components.

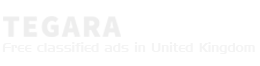

One of the two primary ways for chip creation nowadays, for example, is to use 200mm or 300mm wafers. This is the diameter of the circular silicon wafer that is broken down into numerous smaller chips.

However, owing to a boom in demand for lower-cost chips, which are rapidly being used in a wider variety of consumer goods, the older 200mm technology is in more demand than ever.

In February 2020, industry news site Semiconductor Engineering warned of a chip shortfall due to a scarcity of 200mm production equipment.

Early indicators of shifting demand led to hoarding and advance purchase of chips by certain computer corporations as the epidemic progressed, leaving others scrambling to get the components.

Laptops, tablets, and webcams were necessary for those working from home, and semiconductor businesses were forced to close during the lockdown.

Consumers have had difficulties obtaining the devices they want at times, but producers have previously met demand.

Unfortunate occurrences have recently exacerbated the problem. For example, semiconductor manufacturers in Texas were forced to close due to a severe winter storm, while a fire at production in Japan caused similar delays.

Logistical obstacles are exacerbating the difficulty. According to Oliver Chapman, CEO of OCI, a global supply chain partner, for many years, the cost of shipping was not a massive issue for many IT businesses since their items are generally small, and suppliers could fit multiple of them into a single 40-foot container.

However, due to the epidemic’s sharp changes in demand, the cost of carrying cargo containers throughout the world has skyrocketed. It’s accompanied by higher air freight charges and a shortage of truck drivers in Europe.

Chipmakers are expanding capacity to meet rising demand, but Mr Köse believes it will take time, not least because semiconductor plants cost billions of dollars to build. “That’s not going to be addressed by Christmas, and I have my doubts it’ll be done by Black Friday [November 2022],” he adds.

The tech titans’ CEOs seem to be well aware of this. For example, Intel and IBM’s CEOs have said that chip shortages might last another two years.

“It will take years to create a better balance,” says Seda Memik, an electrical and computer engineering and computer science professor at Northwestern University. She further believes that chip demand has been growing fast that a shortage was “inevitable” at some point.

“It’s quite expensive and requires a well-trained team,” she adds of quickly creating new chip operations. It might be a stumbling obstacle for proponents of “reshoring” or relocating chip manufacturing to a wider variety of countries.

Mr Chapman isn’t sure that the market is ready to do business. However, he believes that chipmakers in Asia, such as those in Taiwan, China, and South Korea, are currently fighting to meet demand and will do so in the future.

According to Mr Köse, consumers are unlikely to notice price rises or severe shortages of digital gadgets this Christmas. Certain high-demand commodities, such as gaming consoles, may become challenging to get, forcing customers to wait months for their desired item. However, he does not expect any significant delays.

Resources:

Leave a Reply